Nanostructured Surfaces by Plastic Injection

Surface engineering is one of the most dynamic industrial areas and features constant technological advances, especially in the manufacture of plastic parts. The presence of micro and nanotextures on surfaces is very common in nature, presenting very diverse functionalities that provide properties such as hydrophobicity (lotus flower), light diffraction (which gives color to butterfly wings), light absorption or dispersion, or hydrodynamic improvements (shark skin), among many more that are feasible for being reproduced artificially with great fidelity.

The generation of microstructures and nanostructures on surfaces makes it possible to change the relationship of a material with its environment. One of the great challenges involves improving the micro and nanofabrication processes of these types of structures and enabling these technologies to be scaled industrially. The texturing of plastic injection molds to then replicate these structures in plastic parts is a solid solution as manufacturing them is large scale and economical.

Within this context, Dr Tomás Baldi Boleda has recently defended his doctoral thesis at IQS, entitled Manufacturing of nanostructured surfaces by plastic injection molding, where his main objective was to obtain affordable and functional textured surfaces. He conducted his thesis under the supervision of Dr Andrés García Granada, professor with the Department of Industrial Engineering, and Dr Carles Colominas Guardia, with the Department of Chemical Engineering and Materials Science, at the IQS School of Engineering.

Textured parts manufactured by plastic injection

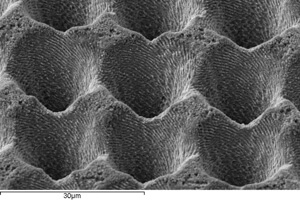

In his research, Dr Baldi explored different methodologies for obtaining textures, on a micrometer and submicrometer scale, using different coating and texturing strategies, including femtosecond pulsed laser texturing, which enable him to obtain periodic surface structures known as Laser-Induced Periodic Surface Structures (LIPSS). These LIPSS structures were characterized by RAMAN spectroscopy, scanning electron microscopy, atomic force microscopy, and X-ray diffraction.

To achieve the objective of obtaining cost-effective micro and nanotextured surfaces that can be manufactured industrially, plastic part manufacturing has been explored through the plastic injection process using injection molds that incorporate the negative of the microtextures. In this case, superhydrophobic surfaces were manufactured, for which Dr Baldi designed and built an injection mold that facilitates changing different surfaces and nanostructures.

It is the first prototype built to achieve this strategy, through which pieces of polypropylene and polycarbonate with superhydrophobic textured surfaces have been successfully obtained, characterized by scanning and confocal electron microscopy. It also represents the first time that the injection parameters – pressure, temperature and cycle time – used to be able to replicate these mold surfaces in the final parts have been described.

Finally, in the last part of his thesis, Dr Baldi studied the manufacture of microfluidic channels for plastic injection. In particular, he developed a strategy for manufacturing the molds for microfluidics, obtaining a complete process that begins in the production of the negative of microfluidic channels with 3D printing, followed by making a copy of the channels in silicone, then finally carrying out a selective coating in nickel, thus obtaining the negative of the channels in the mold where, finally, the microfluidic channels are obtained in polycarbonate pieces by plastic injection.

This thesis has been conducted in collaboration with the companies Fluebetech and Microrelleus, the Association of Industry of Navarre (AIN), the Public University of Navarre (UPNA), the Institute of Nanoscience and Materials of Aragon (INMA), and the National Microelectronics Center (CNM-CSIC) of Bellaterra.

Related publications

– Tomás Baldi-Boleda, Carles Colominas and Andrés García-Granada

Femtosecond Laser Texturization on Coated Steel, Coatings Volume 12, October 2022, Article 1602

– Baldi-Boleda, T.; Sadeghi, E.; Colominas, C.; García-Granada, A.

Simulation Approach for Hydrophobicity Replication via Injection Molding

Polymers Volume 13, 2069

This research has received financing through the IQS grant program for the recruitment of predoctoral research personnel, and has formed part of the PLASTFUN project, included in the Future Industries Community within the RIS3CAT strategy promoted by the Government of Catalonia.

RELATED PEOPLE:

RESEARCH GROUP

Materials Engineering

Industrial Products Engineering Group

Chemical & Synthetic Biology for Biotherapies

RELATED PROJECTS

PLASTFUN (Planta Piloto de piezas plásticas con superficies funcionales avanzadas)