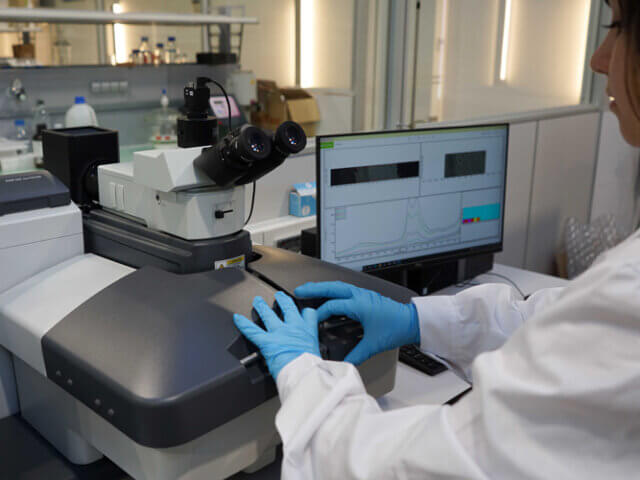

Bioprocess Pilot Plant

Bioprocessing infrastructure and equipment for the development, optimisation, scale-up and manufacturing of test batches. Suitable for microorganisms cultures (bacteria, yeasts and fungi) in batch and fed-batch and in aerobic or anaerobic conditions. Class 1 organisms (non-pathogenic). Includes downstream operations for the first stages of bioproduct isolation.

It features a surface area of 130 m2 including:

- Bioprocessing space, which houses the 144 L bioreactor, auxiliary services and process equipment (DSP) including cell disruption, centrifugation, microfiltration, ultrafiltration and lyophilisation.

- Reagents and Product storage, with a 4ºC cold chamber and a -20C chest for the storage of samples, culture media and production batches that require cold preservation.

- Auxiliary Laboratory, for the preparation of inoculums, culture media and analytical techniques. Equipped with a laminar flow cabinet, fume hood, incubators, baths, centrifuges, spectrophotometer, analyser, and a 10 L bioreactor for inoculum preparation and for preliminary viability and optimisation studies.

144L Biorecator

Bioreactor for cultures, with a net volume going from 20 to 100 L. (Bionet, model F3-100)

EQUIPMENT

144 L Bioreactor (Bionet)

10 L Bioreactor (Bionet)

Tangential microfiltration and ultrafiltration system (Bionet)

Cell disruptor (Gea Niro Soavi)

Process centrifuge (Alfa Laval)

Freeze dryer with chamber (Coolvacuum)

MANAGER

Antoni Planas Sauter, PhD

Head of GQBB Group - Professor - Fellow of the Royal Academy of Sciences and Arts of Barcelona

+34932672000

SEE MORE

BUSINESS SOLUTION AREAS

RESEARCH GROUP

School of Engineering

Biological and Biotechnological Chemistry

Its activity focuses on the identification and molecular analysis of proteins and enzymes as therapeutic targets, together with the design and application of enzymes in biocatalysis and biotechnology with microorganisms.