Flow Chemistry Unit

The Flow Chemistry Unit includes a pilot plant and laboratory equipment for carrying out flow chemistry reactions aimed at the development and industrial scale-up of fine chemistry processes. It carries out research and technology transfer activities for companies in the pharmaceutical and fine chemistry sectors. It has a team of professors and researchers with solid experience in the industrial environment.

Application of new manufacturing technologies in fine chemistry, transforming and optimising batch or discontinuous production systems into continuous production systems with more efficient, stable, safer, faster and cleaner reactions.

- Two Syrris modular reactors: one for laboratory scale and one for process scale-up (kilolab). They operate from microlitre/minute to half a litre/minute. Reaction monitoring and control is performed by process analysis techniques (PAT).

- Fine chemical reaction calorimeter for processes operating with a reaction volume between 1 and 2L, at temperatures between -20°C and 200°C, and pressure between 1 and 60 bar.

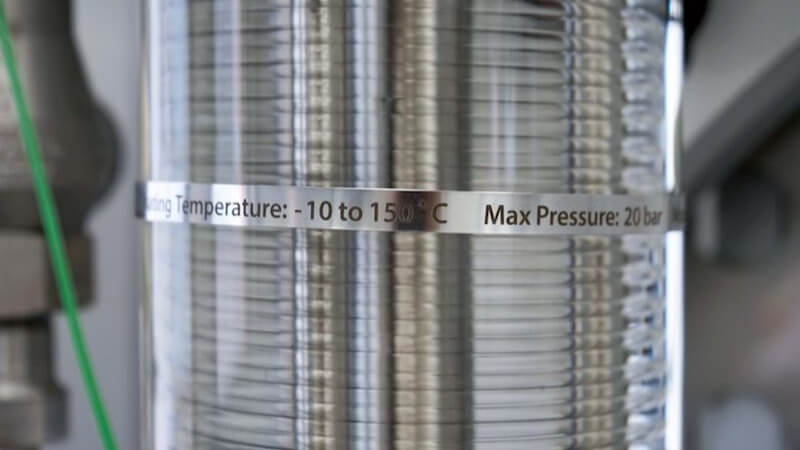

TITAN MODULAR CONTINUOUS FLOW CHEMISTRY REACTOR (SYRRIS)

TITAN modular continuous flow chemistry equipment for process scale-up and batch production up to 1 kg.

EQUIPMENT

TITAN Continuous Flow Chemistry Modular Reactor (Syrris)

ASIA Continuous Flow Chemistry Modular Micro-Reactor (Syrris)

FTIR spectrophotometer (Mettler Toledo)

Raman spectrophotometer (Raman)

Ultraviolet Analyser (Ocean Optics)

RC1 reaction calorimeter (Mettler Toledo)

MANAGER

BUSINESS SOLUTION AREAS

RESEARCH GROUP

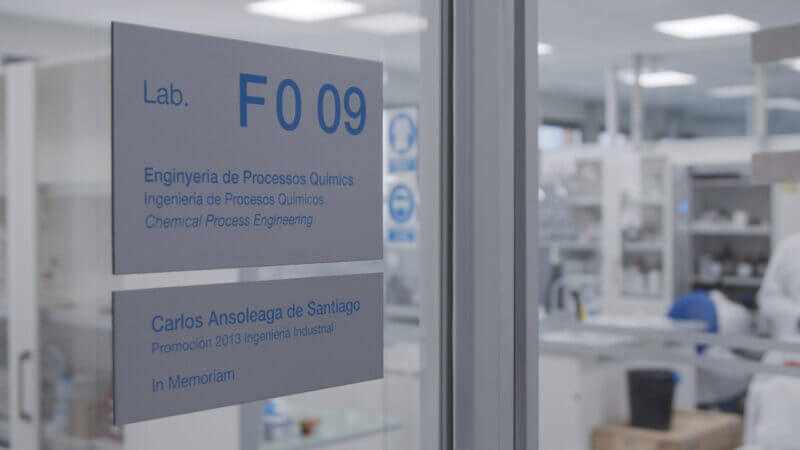

School of Engineering

Pharmaceutical Chemistry Group

The research focuses on two main areas: New Drugs in Biomedicine and Health Sciences and Flow Chemistry Processes.

School of Engineering

Chemical Reactions for Innovative Solutions

CRISOL is a powerful team capable of offering innovative chemical tools that make it real solutions to the challenges of Molecular Science.