Structural solutions through additive manufacturing

The increasingly evident scarcity of resources and the necessary consciousness about sustainability make it essential to tackle the challenge of making better use of materials and optimizing manufacturing processes.

Within this framework, researchers from the Department of Industrial Engineering at the IQS School of Engineering have conducted the New Developments in Lightweight Composite Sandwich Panels with 3D Printed Cores (3DPC, included in the State R&D&I Programme aimed at the Challenges of the Society under the 2017-2020 State Plan for Scientific, Technical, and Innovation Research, within the “Sustainable, intelligent, connected, and integrated transport” challenge.

Many present and the future engineering challenges involve lightening structures or, in other words, creating more resilient structures by making more efficient use of the materials. Moreover, they also involve improving and developing new manufacturing processes that make it possible to tackle these challenges in a more sustainable manner. To achieve this, 3DPC has focused on observing natural structures that have evolved over millennia until they have reached a very high degree of optimization and are now characterized by their rigidity, strength, lightness, and material use, but also by their extraordinary geometric complexity.

New structures developed with 3D printing

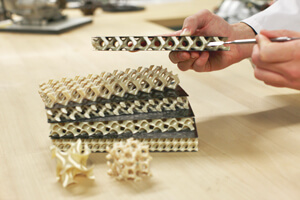

Precisely because of their geometric complexity, it is not feasible to replicate these shapes through conventional manufacturing processes. However, by taking advantage of the latest advances and the potential of additive manufacturing technologies, IQS researchers have been able to reproduce a wide range of natural shapes and develop new bio-inspired designs that, when implemented as a core in hybrid sandwich structures, make it possible to produce lighter, more sustainable, and more efficient functional structural solutions.

Specifically, IQS researchers have designed a total of 48 two-dimensional and three-dimensional periodic cell geometries by combining different designs, cell arrangements, and densities, analysing their mechanical capabilities in parallel and using numerical simulation software to assess their structural functionality.

The material chosen for manufacturing the cores was a high performance polyetherimide: Ultem 9085. In addition to offering an excellent strength-to-weight ratio, this thermoplastic material is FST (Flame, Smoke, and Toxicity) certified, which guarantees that it will self-extinguish and that the smoke it could produce is non-toxic in the event of a fire.

Once the cell nuclei were analysed, they were combined with carbon fibre reinforced polymer (CFRP) skins to form lightweight hybrid sandwich structures. This arrangement makes it possible to take advantage of the low density and thickness of the cell nucleus to increase the inertia of the hybrid structure section and thus maximize its mechanical performance without implying a significant increase in mass.

The excellent results obtained in the 3DPC project now open the door to the use of new materials – in this case metallic – with which the best geometries obtained in this research can be reproduced to obtain structures with even greater performance, thus increasing possible applications.

Related publications

Ariadna Chueca de Bruijn, Giovanni Gómez Gras, Marco A. Pérez; Mechanical study on the impact of an effective solvent support-removal methodology for FDM Ultem 9085 parts, Polymer Testing, 85, May 2020, 106433

Albert Forés Garriga, Marco A. Pérez, Giovanni Gómez Gras, Guillermo Reyes Pozo; Role of infill parameters on the mechanical performance and weight reduction of PEI Ultem processed by FFF, Materials & Design, 193, August 2020, 108810

Ariadna Chueca de Bruijn, Giovanni Gómez Gras, Marco A. Pérez; On the effect upon the surface finish and mechanical performance of ball burnishing process on fused filament fabricated parts, Additive Manufacturing, 46, October 2021, 102133

Albert Forés Garriga, Giovanni Gómez Gras, Marco A. Pérez; Mechanical performance of additively manufactured lightweight cellular solids: Influence of cell pattern and relative density on the printing time and compression behavior, Materials & Design, 215, March 2022, 110474

Ariadna Chueca de Bruijn, Giovanni Gómez Gras, Marco A. Pérez; Selective dissolution of polysulfone support material of fused filament fabricated Ultem 9085 parts, Polymer Testing, 108, April 2022, 107495

Thermal annealing as a post-process for additively manufactured Ultem 9085 parts Ariadna Chueca de Bruijn, Giovanni Gómez Gras, Marco A. Pérez Procedia Computer Science, 200, 2022, Pages 1308-1317

RELATED PEOPLE:

RESEARCH GROUP

Applied Mechanics and Advanced Manufacturing

RELATED PROJECTS

3DPC (Fabricación Aditiva)