New electrochemical lithium sensors

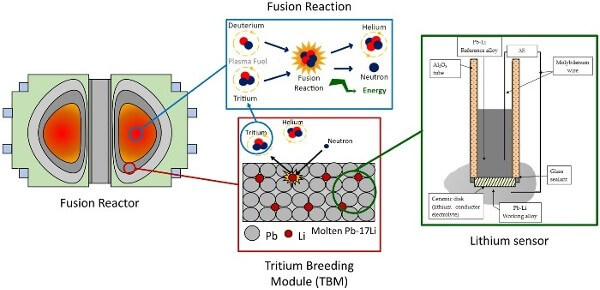

Energy produced by the fusion of atomic nuclei is one of the paths towards a possible source of clean energy in the future. In order to make it a reality, several research groups are working on the construction of fusion reactors that can generate tritium through the nuclear reaction of 6Li with high-energy neutrons. Tritium production will be carried out in the so-called Tritium Breeding Blankets (TBM), one of the essential elements that form part of future fusion reactors and the development of which is crucial to achieving the desired objectives.

Different options for the regeneration of tritium within TBMs are being studied, one of which is the use of the Pb-Li eutectic alloy, where lithium will be consumed and controlling the concentration of this element through the use of continuous electrochemical sensors will be crucial.

Within this research context, Dr Marc Nel·lo recently defended his doctoral thesis which was conducted at IQS. Entitled Development of Li sensors for their application in fusion technology, his thesis was supervised by Dr Jordi Abellà and Dr Sergi Colominas with the Electrochemical Methods Laboratory under the Analytical Chemistry Group (QuAN) at the IQS School of Engineering.

Lithium control tools in extreme conditions

In his doctoral thesis, Dr Nel·lo developed electrochemical lithium sensors based on solid lithium-conducting electrolytes that are capable of working in very high temperature conditions.

The first step was the selection of the most suitable electrolytes for the construction of the sensors, with the requirements of being stable at high temperatures (above 600 °C), having low reactivity when in contact with the metallic Li, and having high ionic conductivity. The selected ceramics were Li6BaLa2Ta2O12 (LBLTO) and Li6La3Ta1.5Y0.5O12 (LLTYO), both satisfactorily synthesized and sintered in this thesis, and with sufficiently high ionic conductivities that permit their use in electrochemical sensors.

Subsequently, and for the very first time, the electrochemical sensors based on these materials were designed and built, which have been evaluated in the extreme conditions described above and with both electrolytes showing excellent results. These potentiometric sensors have made it possible to successfully determine the nominal concentration of lithium present in prepared samples of Pb-Li alloy.

In short, this research has developed analytical instruments that are capable of monitoring the concentration of lithium in fused Pb-Li alloys, which represents a great advance on the path towards fusion energy and opens many doors to the future of this energy.

Related publications

Marc Nel·lo, Oscar Ferrer, Sergi Colominas, Jordi Abellà; Lithium sensors based on Li6La3Ta1.5Y0.5O12 and Li6BaLa2Ta2O12 garnet electrolytes for molten lead alloys, 339, Sensors and Actuators B:Chemical, July 2021, 129831.

Marc Nel·lo, Sergi Colominas, Jordi Abellà; Lithium conducting ceramics for future electrochemical sensors in molten metals, 146, Fusion Engineering and Design, September 2019, 1216-1220

This research has been carried out within the framework of the project “Development and Application of sensors for molten metals in fusion reactors (RTI2018-095045-B-I00)” as part of the 2018 “Research challenges” call for projects under the Spanish R&D+i programme aimed at the challenges of society, with the Ministry of Science and Innovation and the State Research Agency.

RELATED PEOPLE:

RESEARCH GROUP

Electrochemistry and Bioanalysis Group

RELATED PROJECTS

SEMOLMETFUS (Desarrollo y aplicación de sensores para metales fundidos en reactores de fusión)