The IQS Industrial Products Engineering Laboratory equipment has been expanded with the recent incorporation of the Form 3BL 3D printer, for the manufacture of full-scale polymeric arteries.

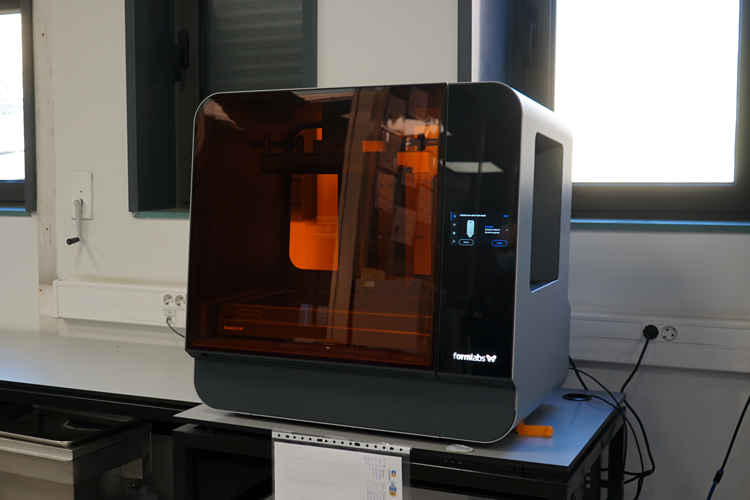

The new Form 3BL printer in the IQS LEPI laboratory

Thanks to the funding obtained by the Vascular Engineering and Applied Biomedicine Group (GEVAB) within the framework of the CaixaImpulse Consolidate 2020 project, the Industrial Products Engineering Laboratory (LEPI) at the IQS School of Engineering now has the most innovative and complete Formlabs 3D printer: the Form 3BL.

Among many options available, this 3D printer will make it possible to manufacture large medical devices and produce full-scale anatomical models using biocompatible and sterilizable materials. Furthermore, the Form 3BL incorporates the new LFS (Low Force Stereolithography) printing technology which facilitates manufacturing professional quality parts in an academic setting.

Applications of the new Form 3BL

The applications of the Form 3BL are mainly focused on the healthcare sector and medical research.

One of the greatest advantages of this printer is the possibility of manufacturing different aortic dissection models, obtained from images of patients, in a single piece. Thanks to the wide range of printing materials, these models can also be manufactured with flexible, elastic, and transparent materials that will allow the team of researchers from the GEVAB group to conduct tests to develop the medical device they are working on in collaboration with the IQS spinoff Aortyx.

The large dimensions and excellent properties of the 3D aorta models obtained with the new Form 3BL will enable the researchers to test their product in a simulated environment that recreates the actual scenario in which the use of the device is expected as closely as possible.

Therefore, this new acquisition by the LEPI laboratory represents the starting point for the upcoming steps in biomedical research at IQS. This research will undoubtedly be continued in the near future by other groups and sectors that can also benefit from the most advanced 3D printing techniques on the market.